The Duty of Plastic Injection Molding in Creating Cost-Effective Industrial Parts

The Duty of Plastic Injection Molding in Creating Cost-Effective Industrial Parts

Blog Article

Recognizing the Basics of Plastic Shot Molding Procedures

Plastic shot molding acts as a keystone of modern-day manufacturing, supplying a systematic strategy to producing intricate parts with accuracy. This process not only incorporates the fundamental actions of melting and injecting materials into mold and mildews but also entails a nuanced understanding of numerous influencing elements, such as temperature and stress. As industries progressively require efficiency and high quality, the details of this method become a lot more important. Checking out these vital components could disclose just how even minor changes can cause considerable improvements in production outcomes, questioning regarding the capacity for development in this well-known process.

What Is Plastic Shot Molding?

Plastic shot molding is a widely utilized manufacturing process that transforms thermoplastic and thermosetting products into precise and complex forms. This technique is preferred for its ability to generate high quantities of similar components with exceptional precision, making it an essential method in different markets, including automobile, customer products, and clinical devices.

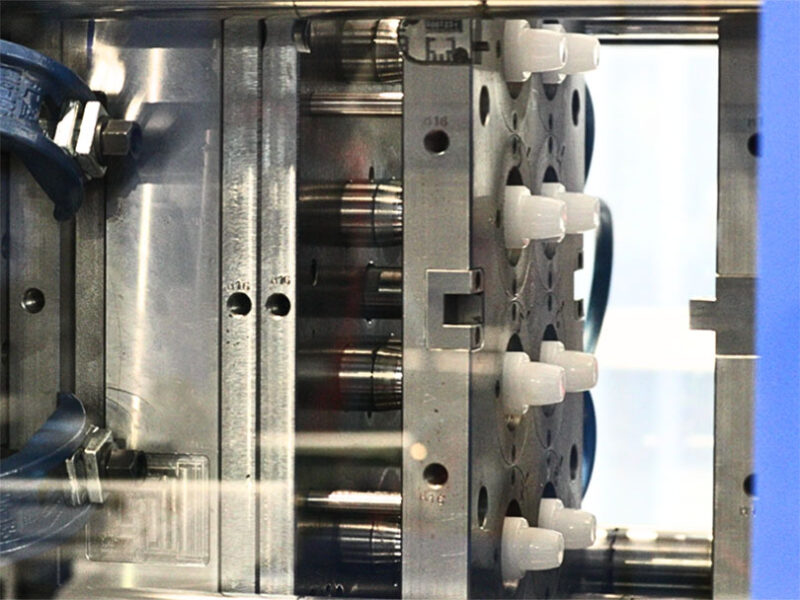

The procedure includes thawing the selected plastic product and infusing it right into a mold and mildew under high pressure. The mold and mildew, created to the specs of the preferred component, permits the molten plastic to materialize as it cools and solidifies. As soon as the material has actually set, the mold and mildew is opened, and the finished component is expelled.

Plastic shot molding offers a number of advantages, consisting of reduced waste, uniformity in manufacturing, and the capability to integrate detailed styles that might be testing with various other making methods. In addition, it supports a broad variety of materials, each giving one-of-a-kind homes that can be tailored for details applications. As sectors proceed to innovate, plastic shot molding stays at the center, enabling the advancement of innovative items that satisfy advancing customer demands.

The Injection Molding Process

The injection molding procedure is an innovative method that entails a number of vital phases to produce high-quality plastic parts. At first, plastic pellets are fed right into a heated barrel where they are merged a thick fluid. This molten plastic is then infused under high pressure into a precision-engineered mold, which forms the material into the desired type.

As soon as the mold and mildew is loaded, the plastic is permitted to strengthen and cool down, taking the shape of the mold and mildew dental caries. Air conditioning time is crucial, as it affects the cycle time and the final buildings of the shaped component. After enough air conditioning, the mold opens, and the ended up part is expelled using ejector pins.

Materials Made Use Of in Shot Molding

Different materials can be used in the injection molding procedure, each offering distinct residential properties that accommodate specific applications. One of the most frequently used products consist of thermoplastics, thermosetting plastics, and elastomers.

Thermosetting plastics, like epoxy and phenolic resins, undertake a chemical modification during the healing process, causing an inflexible, inflexible framework. These products are excellent for applications needing high warm resistance and structural integrity, often made use of in automotive parts and electric insulators.

Elastomers, visit this page consisting of silicone and rubber-based products, offer adaptability and durability. Their special buildings make them appropriate for applications that require elasticity, such as gaskets and seals.

Additionally, specialized products like bio-based plastics and composites are gaining traction for their ecological benefits and enhanced performance characteristics, widening the scope of shot molding applications in various markets. Comprehending the buildings of these products is crucial for choosing the proper kind for certain tasks.

Advantages of Shot Molding

Injection molding sticks site here out as an extremely efficient manufacturing procedure that provides countless advantages for creating intricate parts with accuracy. One of the most significant advantages is the capability to develop detailed designs that would be challenging or impossible to accomplish with various other techniques (Plastic Injection Molding). The procedure enables thorough attributes and limited resistances, ensuring top quality elements

In addition, shot molding is known for its rapid manufacturing capabilities, making it an optimal option for high-volume manufacturing. Once the mold is developed, components can be created quickly, reducing lead times and raising general performance. This effectiveness not only reduces production prices but likewise provides an one-upmanship in the market.

The flexibility of products utilized in shot molding even more improves its charm. A large range of thermoplastics and thermosetting polymers can be employed, enabling manufacturers to choose products that best fulfill their details requirements, including flexibility, warm, and stamina resistance.

Additionally, the process reduces waste, as excess product can usually be recycled and reused. This sustainability facet contributes to a decreased environmental impact, making shot molding a liable manufacturing choice. Overall, the benefits of injection molding make it a favored method for lots of markets.

Factors Influencing Product Top Quality

While countless elements can affect product quality in shot molding, understanding these aspects is crucial for attaining ideal outcomes. Secret aspects consist of material option, processing criteria, and mold and mildew layout.

Product choice plays a vital duty, as various polymers display special properties that affect flowability, toughness, and thermal stability. Insufficient material option can cause flaws such as bending or incomplete filling.

Handling criteria, consisting of temperature, cycle, and pressure time, have to be thoroughly controlled. Variations in these settings can cause incongruities in component dimensions and surface area coating. For example, exceedingly heats may create deterioration of the polymer, while insufficient pressure can cause short shots.

Mold and mildew design is equally vital, as it establishes the circulation of the molten plastic and the cooling process. Improperly designed mold and mildews may result in unequal cooling prices, causing residual anxieties and dimensional inaccuracies.

Final Thought

In final thought, plastic shot molding acts as a crucial production procedure that makes it possible for the reliable production of high-grade elements. Proficiency of the shot molding procedure, consisting of the understanding of materials and the impact of numerous factors on item top quality, is essential for attaining optimum results. The benefits of this method, such as cost-effectiveness and style flexibility, additional emphasize its significance throughout numerous industries, strengthening its standing as a favored choice for high-volume manufacturing.

Plastic shot molding offers as a cornerstone of modern-day manufacturing, supplying a methodical approach to creating complex parts with precision.Plastic shot molding uses several benefits, consisting of reduced waste, consistency in manufacturing, and the capacity to include complex designs that might be testing with other manufacturing techniques (Plastic Injection Molding). you can look here As markets proceed to introduce, plastic shot molding remains at the forefront, making it possible for the development of innovative products that satisfy developing consumer needs

The injection molding procedure is an advanced technique that involves several key stages to create high-quality plastic parts.In final thought, plastic injection molding serves as an essential production process that allows the efficient production of high-quality parts.

Report this page